The Full Automotive Accessories Center In Memphis!

The Full Automotive Accessories Center In Memphis!

upgrade your vehicle today!

When you are looking to upgrade the interior or exterior of your vehicle, then you need to bring it to 901 Sounds in Memphis! We are experts in giving your vehicle an upgrade no matter the make and model. We specialize in upgrading to mobile start, security, installing Carplay, audio, video, window tinting, rims, lifts, and, adding off-road accessories and so much more! We also offer financing for anyone that qualifies as well as credit assistance. Call us today at

901-372-9922 or bring your vehicle on by our store now!

Why You Can Trust 901 Sounds For Your Full Automotive Accessories Installations and Repairs

At 901 Sounds, we take pride in providing our customers with vehicle upgrades they will love. Our favorite part of our day is when we present our customers with their vehicle enhancement and we see the big smiles on their faces. We work on all types of vehicles, not just luxury and sports cars! We work on all types and years of cars, Motor Homes, Motorcycles, Cargo and Travel Trailers, Big Trucks, Little Trucks, Big Boats, Small Boats. Radio, Stereo, Mobile Video, CD Player, GPS Navigation, Hands-Free Bluetooth, iPod Integration, Car Audio or whatever else you need! We can also deliver your vehicle to you!

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButtonSlide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

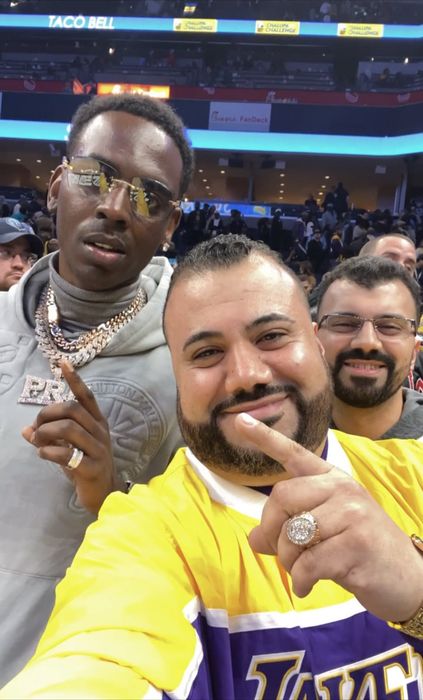

See Why Our Customers Choose Us For Their Automotive Modifications And Enhancements!

Slide title

Mo, at 901SOUNDS, went above and beyond again. Very knowledgeable about the products, and willing to share his knowledge, instead of trying to sell/or up sell. I told him what I wanted the product/s to do with future capability......he pointed me to the exact product & explained the difference in the products....

The install team @ 901SOUNDS must really know their stuff also, I was quoted a 5 hour slot to complete the install, although I was late for my appointment...... My install was completed very fast!!!

I WILL DO BUSINESS HERE AGAIN IN THE NEAR FUTURE.... LOOKING FORWARD TO A STAR HEADLINER W/TWINKLE MODE & UPCOMING SHOWS & SOUND COMPETITIONS!

💯

- D Bow

Button

I was looking for a remote start and car alarm my brother recommended that I check them out. I went in to the store every one was helpful and friendly. Any questions that I had they answered them with no problem. Long story short Tasha she helped me with choosing the right alarm system and I love it. I will be back

- Tawanda C.

Button

Tasha was real nice and always answer all of my questions when I asked her something and she is always on the move to help other peoples at the work place keep of the good work Tasha

- Eric S.

Button

Very professional and took great care of me and my car. I would definitely recommend !

- Tanekia J.

Button

Slide title

I was looking everywhere for an auto tinting for my husband’s new 2020 truck for his front windows. Nobody would take me without an appointment and he needed it for a special occasion as we traveled the following weekend. Tasha Clark took my call and booked me for next day. And the Kobe was very professional and even matched the factory tint very well. I’m so pleased I booked an additional appointment for myself. I highly recommend them and the price was great.

- Yolanda F.

Button

Slide title

Mo, at 901SOUNDS, went above and beyond again. Very knowledgeable about the products, and willing to share his knowledge, instead of trying to sell/or up sell. I told him what I wanted the product/s to do with future capability......he pointed me to the exact product & explained the difference in the products....

The install team @ 901SOUNDS must really know their stuff also, I was quoted a 5 hour slot to complete the install, although I was late for my appointment...... My install was completed very fast!!!

I WILL DO BUSINESS HERE AGAIN IN THE NEAR FUTURE.... LOOKING FORWARD TO A STAR HEADLINER W/TWINKLE MODE & UPCOMING SHOWS & SOUND COMPETITIONS!

💯

- D Bow

Button

I was looking for a remote start and car alarm my brother recommended that I check them out. I went in to the store every one was helpful and friendly. Any questions that I had they answered them with no problem. Long story short Tasha she helped me with choosing the right alarm system and I love it. I will be back

- Tawanda C.

Button

Tasha was real nice and always answer all of my questions when I asked her something and she is always on the move to help other peoples at the work place keep of the good work Tasha

- Eric S.

Button

Very professional and took great care of me and my car. I would definitely recommend !

- Tanekia J.

Button

Slide title

I was looking everywhere for an auto tinting for my husband’s new 2020 truck for his front windows. Nobody would take me without an appointment and he needed it for a special occasion as we traveled the following weekend. Tasha Clark took my call and booked me for next day. And the Kobe was very professional and even matched the factory tint very well. I’m so pleased I booked an additional appointment for myself. I highly recommend them and the price was great.

- Yolanda F.

Button

DUE UPON SIGNING

$70

No Credit Needed

Instant Decisions

Easy Payment Options

No Application Fee

DUE UPON PURCHASE

$49

No Credit Check

Instant Decisions

Easy Payment Options

No Application Fee

DUE UPON PURCHASE

$49

No Credit Check

Instant Decisions

Easy Payment Options

No Application Fee

DUE UPON PURCHASE

$39

No Credit Check

Instant Decisions

Easy Payment Options

No Application Fee

ZERO DOWN ZERO INTEREST

UP TO 12 MONTHS

SUBJECT FOR CREDIT APPROVAL